Detecting flexible display defects with one-shot image

- 3D measurement technology to test complex curved surfaces in real time -

# Optical components used in flexible displays, a core component of foldable phones, as well as smart glasses and VR devices are ‘freeform surfaces’ with complex forms. With such complex surface forms, products have to be inspected thoroughly, but defects still occur frequently, causing concern to the consumer.

A measurement technology that can inspect the form of complex curved surface components in real time during the production process has been developed at the Korea Research Institute of Standards and Science.

Principal Research Scientist Young-Sik Ghim of the KRISS Advanced Instrumentation Institute is the researcher behind the 3D freeform surface measurement technology that can detect surface changes and defects on advanced components such as flexible displays, automobile exteriors, ultrathin films for next generation secondary batteries, etc., using just a single image. This technology is unaffected by the shape and size of the object being measured, and can be installed directly into industrial production lines thanks to the simplicity of its composition.

Freeform surfaces* are surfaces that are not just flat or round, but are asymmetrical about all axes. Freeform surfaces are being applied to numerous products in our daily lives, as they evolve to become smaller, lighter, and more aesthetically pleasing from the design perspective.

* Freeform surface: A free curved surface that is asymmetric to every axis. Freeform surface technology offers greatly enhanced optical performance compared to spherical or aspherical optical surfaces, while facilitating smaller and lighter devices that are also aesthetically pleasing.

Freeform surfaces, which previously were mainly used in large components such as outer shells for aircraft, spacecraft and vehicles, are now being expanded to high precision component parts such as displays and semiconductors with improved fabrication technologies.

However, this means that the problem of defects such as surface flaws and damage has become more frequent, but such defects are very difficult to detect using conventional measurement technologies, which only work on simple structures and do not have the sub-nanometer level of accuracy required by freeform surfaces. Another huge problem is that the measurements take too much time, making it impossible to respond immediately to various defects occurring in real time.

Now, KRISS Principal Research Scientist Young-Sik Ghim has developed a ‘real-time 3D freeform surface measurement technology’ that successfully resolves these issues and goes beyond the limitations of conventional technology. With this, real-time surface inspection of freeform surfaces at highly precise nanometer-level resolution can be achieved using just a single image. As the process is not complicated or time consuming, it can be conducted in real time, making it resistant to changes in the external environment and thus more accurate.

The process consists of casting an optimized composite grid pattern on the target, and analyzing the resulting image using an independently developed algorithm. When the composite grid pattern is cast on the surface of a product, surface defects such as flaws and damage are highlighted, making them easy to detect.

“The technology has been perfected to a high degree with automation and modularization, so that it can be applied at any stage in actual production processes,” Principal Research Scientist Young-Sik Ghim explains, adding “we hope it will be used as a key inspection equipment technology in various advanced industries.”

This technology was transferred to Nexensor, an optical measurement equipment and module company, for a fixed royalty of KRW 110 mil. and a running royalty of 2% revenue. It was also published in the international journal “Scientific Reports” (IF:4.122).

○ Images related to the study

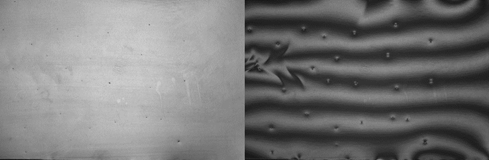

▲ Detection of defects in ultrathin films for secondary batteries:

Comparison of image from conventional technology (left)

and image from KRISS-developed new technology (right)

- Surface defects show more prominently, making them much easier to detect.

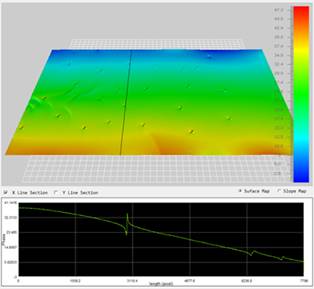

▲ Result of surface defect detection in ultrathin films for secondary batteries using 3D freeform surface measurement technology

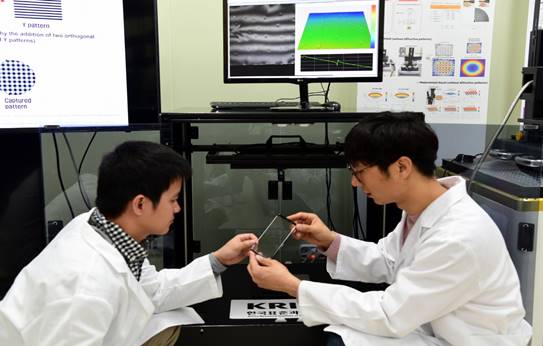

▲ 3D freeform surface measurement equipment developed by KRISS Principal Research Scientist Young-Sik Ghim

-(Left) Testing equipment for small-scale area measurement / (Right) Robot arm based testing equipment for large-scale area measurement

○ What sets this achievement apart?

The 3D freeform surface measurement technology independently developed at KRISS requires only a single composite pattern image to take measurements, making it resistant to external environmental noises, and able to take real-time measurements of even dynamic objects.

Furthermore, it can take precise measurements of various freeform surfaces at nanometer-level resolution. The KRISS team also developed an algorithm that corrects for the distortion of the composite pattern due to changes in reflectance of the specimen, as well as non-linear response error of the measurement device, improving the precision by over 30%.

○ What are its applications?

1. High value-added advanced industries – surface defect detection in flexible displays, next generation secondary batteries etc.

: The technology enables ultra-high-speed detection of a wide range of opaque surface defects that were not detectable in existing equipment, such as marks, protrusions, scratches etc. for flexible substrates and next generation secondary batteries etc. This could be used in the development of testing/measurement devices for newly arising market needs in the future.

2. Automobile and shipbuilding industries – visual inspection

: Visual inspection of automobile and ship parts that had to be done manually due to the lack of measurement technology can be automated.

3. Aerospace and national defense – high precision optical component inspection

: It will become possible to take 3D surface measurements of high precision optical components that play a crucial role in future industries such as satellites and unmanned aerial vehicles.

▲ KRISS Principal Research Scientist Young-Sik Ghim (right) and his team are checking a smartphone cover glass panel.

原文源自KRISS网站,版权归其所有。如有侵权,请联系,第一时间删除。